Ultra-fast charging lithium-sulfur batteries capable of powering long-range EVs and commercial drones

Engineers at Monash University have developed an ultra-fast charging lithium-sulfur (Li-S) battery, capable of powering long-range EVs and commercial drones.

The novel batteries double the energy density of conventional lithium-ion batteries while being significantly lighter and more cost-effective. With further development, the technology could become a viable option for electric aviation in the future.

Until now, lithium-sulfur batteries have not been commercially viable because their complex chemistry makes them very slow to charge.

The research, a decade in the making and published in Advanced Energy Materials, marks a transformative step in renewable battery technology and sets a new benchmark for practical lithium-sulfur prototypes.

Malesha Nishanke is the paper’s first author and a Ph.D. candidate in the Monash Nanoscale Science and Engineering Lab (NSEL).

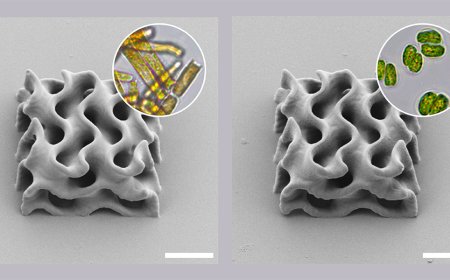

"Inspired by the chemistry of Betadine, a common household antiseptic, we found a way to accelerate charge and discharge rates, making them a viable battery alternative for real-world heavy-duty use," he said.

Co-lead author of the paper, Dr. Petar Jovanovic, believes that Li-S batteries could power commercial drones, bringing high-performance, sustainable electric aviation closer to reality.

“This represents a major step forward in making Li-S a viable option not only for long-range EVs, but especially in industries such as aviation and the marine industry that require fast, reliable power that is extremely lightweight,” Dr. Jovanovic said.

In an electric car, Li-S batteries could provide an additional 1,000 kilometers of power on a single charge while reducing recharge times to hours.

“Imagine an electric car that can go from Melbourne to Sydney on a single charge or a smartphone that charges in minutes – we are on the path to making this a reality,” Dr. Jovanovic said.

Professor Mainak Majumdar, co-principal researcher and director of the ARC Research Hub for Advanced Manufacturing with 2D Materials, said Li-S technology typically struggles to maintain high performance without degrading quickly, but this game-changing battery can take a lot of energy. out at once without breaking down. The batteries are cheaper and store more energy.

Professor Majumdar said, “We have used the unique chemistry of sulphur to create a battery that is both safer and more efficient. With our new catalyst, we have overcome one of the last remaining barriers to commercialisation – charging speed,” said Professor Majumdar. “Our catalyst significantly improved the C-rate performance of Li-S batteries, as demonstrated in early proof-of-concept prototype cells.

"With commercial scaling and larger cell production, this technology can deliver energy densities of up to 400 Wh/kg. This makes it suitable for applications that require dynamic performance, such as aviation, where batteries need to operate at high C-rates during take-off and switch to lower C-rates during cruising. Li-S batteries are a greener alternative to the materials traditionally used in Li-ion batteries, which rely on limited and often environmentally harmful resources such as cobalt."

With the global lithium-sulfur battery market expected to be worth $209 million by 2028, Professor Majumdar said, adding that Monash's pioneering work could put Australia at the forefront of the rapidly expanding industry.

"This emerging industry has the potential to create jobs, drive economic growth and establish Australia as a key player in the market," Professor Majumdar said. "As demand for high-performance batteries increases, investment in cutting-edge technology will have long-term benefits for job creation and economic growth."

The research team continues to innovate. Currently, they are refining new additives that promise to further speed up both charging and discharging times, as well as methods that reduce the amount of lithium needed.